We take pride in our business that has been in the Hartsen family for over 79 years

Why Us?

- Get the Facts from the Experts.

- Comprehensive, Comfortable and Caring Purchasing Experience.

- Professional, Expert Installation. Period.

- Unmatched Service After the Sale.

About Us

Customers shopping for cost-effective and fuel-efficient supplemental home heating sources will find one of the most extensive displays of stoves, fireplaces, and inserts in the greater Rochester NY area. Our heating experts will help you chose a solid-fuel or gas heating appliance that is correctly sized for your home for safety and efficiency.

We offer a wide variety of top name brands, and will work with you to match the décor of your home and provide the warmth, comfort, and style you are looking to create. Our goal is to offer a perfect installation – from advising you on your selection to completing the project – making sure there is no heat loss when the appliance is not in use, ensuring energy efficiency, and assuring you that our product and installation process exceeds safety regulations and industry standards.

We encourage you to visit the Stove Shoppe and see our vast display of working stoves, inserts, and fireplaces. We have designed the area to showcase a variety of decorating schemes, fireplace and stove options, and feature all the top brands in the industry.

We take pride in our business that has been in the Hartsen family for over 79 years and appreciate the business of our customers.

Williamson Hardware is also an Ace Hardware store, providing a full service resource for heating, plumbing, electrical, cleaning, lawn and garden, home decorating, and security supplies.

GAS

WOOD

ELECTRIC

COAL

Much More Than Just Stoves!

While you’re here visit our Country Attic, Country Cellar

and fully stocked Ace Hardware…truly something for everyone!

CLEANING & LAWN & GARDEN

SAFETY & SECURITY

PAINT & WALLPAPER

ELECTRICAL SUPPLIES

TOOLS & HARDWARE

PLUMBING

THE COUNTRY ATTIC

Our Country Attic has everything you need for your country home: including country curtains, framed prints, lamp shades, candles, bird houses, benches, flags, rugs, collectibles, shelves, made in USA wooden sighs & furnishings, lodge, outdoor and garden decor.

The Country Attic also offers gifts and cards for Weddings, Anniversaries, Baby Showers and Birthdays.

Stop buy and browse through our year-around Christmas Room. Always on display are trees, wreaths, garlands, a lighted village with accessories, Santa’s snowmen, lights strands in many styles and colors…and thousands of unique ornaments to choose from.

THE COUNTRY CELLAR

Looking for an outdoor experience? Our Country Cellar is filled with items to enhance your outdoor living space including hammocks, BBQ grills & accessories, patio furniture in metal, plastic & wood, table umbrellas, chimes, lanterns, decorative flags, torch lights, outdoor theme decorations, & birdhouses.

For sports enthusiasts, the sport shop includes guns & ammunition, camping gear, fishing poles, lures, & knives.

The friendly, hometown staff at Williamson Hardware, Inc. is on hand seven days a week to assist you with your purchase of sporting equipment and the perfect deck and patio furnishings for the exterior of your home.

Our Hearth Referral Program

Refer a friend to Williamson Hardware, and when they purchase a qualified product, you will receive a $50 Ace Hardware Gift Card!

Parts and Accessories

We offer a huge inventory of hard to find parts and accessories for most major brands of wood, gas and coal stoves, inserts and fireplaces. We can also locate parts for many older and discontinued Brands – We have contacts throughout the industry from our 70+ years in the stove business. If it is available anywhere we should be able to find it for you.

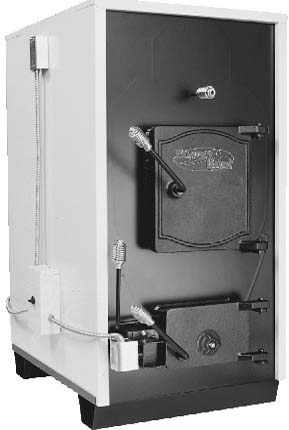

FURNACES

Choose the right wood or coal fireplace for you!

A wood or coal furnaces is a unique independent or supplemental home heating option that provides high heat output. Designed with maximum efficiency in mind, these units feature automatic controls and adjustable baffling for an extended burn.

These furnaces will keep your home and family warm through even the most frigid winter nights. Our heating experts will help you choose a solid-fuel heating appliance that is correctly sized for your home, ensuring safety and efficiency. You can be secure in the knowledge that our furnaces conform to an internationally recognized standard for safety and quality.

Stop in today to discuss wood and coal furnace heating options with the friendly staff at Williamson Hardware.

MANTELS

Choose the right mantel for you

“A picture is just a picture, but a framed picture is finished art.” The same principal applies to your fireplace. Handcrafted mantels by JC Huffman, Grand Mantel, Mantel Expressions, Fires of Tradition and Solus along with other leading manufacturers are the perfect frame for any fireplace you choose. If you’re looking to enhance your fireplace by adding a mantel, there are plenty of choices to spark your interest. Fireplace mantels come in a wide variety of shapes, sizes, materials and designs. To choose a mantel that best suits your needs and your decor, consider the size of your fireplace as well as available wall space.

Some of the most popular materials for mantel construction are marble, stone and wood. Stone mantels, well suited to large fireplaces, come in many different colors and types of stone, including limestone, granite, concrete and river rock.

Highly popular, wood mantels range from simple, rustic beams to intricately carved shelving. Wood mantels come in many varieties of hardwoods such as cherry, oak and cedar. Unlike stone mantels, wood mantels can be painted or stained. Marble mantels create an elegant, rich look when placed atop a fireplace. Best suited to formal decor, a marble mantel, due to the hard nature of the material, is sturdy and long-lasting.

Need Your Chimney Cleaned?

We recommend chimneys get a thorough cleaning at least once a year, depending on use.

The inside walls of the chimney flue are exposed to hot gases and smoke from the burning fuel. During the year, the build-up of smoke can result in the formation of a residue called creosote on the walls of your chimney. Creosote builds up and may take the form of a tar like substance which is highly flammable and could catch fire. A chimney fire can destroy your chimney and spread throughout the house. By cleaning the chimney to remove the residue, you maintain the safety and efficiency of your chimney thus preventing chimney fires. Also a clean chimney will help to maintain good draft so that dangerous fumes can exit your home properly, leaving it cleaner, smelling better and helping to insure the safety of you and your family.

READ MORE

Our team of professionally trained chimney experts care about you and your family’s home and safety. That’s why, when we come out for a service call, we will make sure that there are no existing or potential chimney hazards to your home. We check for broken and cracked flues, missing mortar from joints, cracked crowns, damaged caps, animal infestation and much more. After we are finished we will discuss our findings with you and recommend solutions if needed so you are safe to use your fireplace and chimney. As our reputation for quality service and devotion to customer satisfaction has spread, our family owned business has grown greatly from its early beginnings in 1940. We are very proud of our high rate of “CUSTOMERS FOR LIFE” and their referrals. Visit the Stove Shoppe for details on fireplace and stove maintenance, and for supplies and accessories. Our friendly staff is available seven days a week to assist you.

OUR SERVICES

- CHIMNEY CLEANING AND INSPECTIONS

- STAINLESS STEEL CHIMNEY RELINING

- CHIMNEY CAP INSTALLATION

- CHIMNEY CROWN REPAIRS

- DAMPERS REPAIRED OR REPLACED

- ANNUAL PREVENTIVE MAINTENANCE PROGRAM

- COMPLETE SERVICE & REPAIRS ON ALL BRANDS OF WOOD, COAL & GAS PRODUCTS

- STOVES REBUILT

- REPLACEMENT OF BROKEN GLASS

- CUSTOM WOOD MANTELS

- REFACING EXISTING FIREPLACES

- CUSTOM CERAMIC TILE HEARTHS

- CUSTOM COLOR PAINTING

- CUSTOM-MADE SURROUNDS FOR FIREPLACE INSERTS

- GAS LINE PIPING INSTALLED BY CERTIFIED INSTALLERS

- 2100 DEGREE CHIMNEYS INSTALLED FOR WOOD & COAL STOVES & FIREPLACES

SERVING THE GREATER ROCHESTER AREA

Arcadia, Batavia, Bergen, Bloomfield, Brighton, Brockport, Caledonia, Canandaigua, Cato, Chili, Churchville, Clarkson, Clyde, Fairport, Farmington, Gates, Genesee, Geneva, Greece, Henrietta, Hilton, Honeoye, Honeoye Falls, Irondequoit, Lyons, Macedon, Marion, Middlesex, Naples, Newark, North Rose, Ontario, Palmyra, Penfield, Penn Yan, Pittsford, Pultneyville, Rose, Sodus, Sodus Point, Victor, Waterloo, Webster, Williamson, and Wolcott

Your “Burning” Questions (aka FAQs)

WOOD STOVES

invisible

What is the difference between catalytic and non-catalytic wood burning stoves?

What's the difference between an EPA stove and a non EPA stove?

How is zone heating different than central heating?

Where should I locate my new stove?

Why does the glass on my wood stove soot up?

Does my wood stove need floor protection?

Why does my wood stove draft poorly?

Invisible

Can I install a wood burning insert into my factory built fireplace?

Is a wood burning fireplace insert right for me?

How do I measure my fireplace for an insert?

WOOD BURNING FIREPLACE INSERTS

invisible

Can I install a wood burning insert into my factory built fireplace?

Those that are listed have very exacting installation requirements that may be difficult if not impossible to achieve.

We highly recommend not installing an insert into one of these types of fireplaces.

Is a wood burning fireplace insert right for me?

Here are a few guidelines and suggestions when shopping for that new insert. First be sure to bring in the measurements of your existing fireplace, width, height and depth are the most important. Many customers take a digital photo of their fireplace and bring it in, which helps us immensely.

CHIMNEY The first thing we do when installing a fireplace insert is to toughly clean your chimney. We want to install the insert into a clean environment so no odors can come back into the house.

CHIMNEY LINERS Fireplace chimney flues are oversized, so installing an insert will require a stainless steel chimney liner to be installed from the insert to the top of the chimney. All gas inserts require aluminum liners to be installed to the top of the chimney. The reason for this is that the new insert is so efficient that it can’t keep the big old masonry chimney hot enough to establish a good draft.

ELECTRIC Many inserts use electric blowers to extract and distribute the heat from the inserts firebox. A nearby electric outlet is required or to eliminate the exposed cord from the surround you may wish to have us install a UL approved hidden wire kit.

SIZING Inserts are sold as two or more components: the insert plus a surround panel and sometimes an optional front. The insert must physically fit into the firebox. The surround panel is designed to cover the gap between the insert and the actual fireplace opening size. Surround panels are offered in differing sizes and styles giving each insert several options.

CLEARANCES Each product is tested and listed to minimum clearances from combustible top and side fireplace trim as well as from combustible mantles. The dimensional depth of the facing trim and of the depth of mantle is important factor when measuring.

HEARTH EXTENSION All wood inserts require the hearth to extend in front of the insert opening. This is a stated distance that varies with each product and is stated in the product manual.

How do I measure my fireplace for an insert?

Second, measure the Height at the front from the bottom of the fireplace to the top of the opening.

Then measure the Depth of the fireplace from the back to the front of the opening in the middle of the fireplace. We realize that most fireplaces have tapered sides and that is ok.

If you have a digital camera or one on your phone, simply take a couple of photos of your fireplace and bring them in with your dimensions. This is like us being there, and is very helpful to us.

We are also happy to come out to your home, at no charge, to help you if you should need it.

VENTING SYSTEMS

invisible

Can I vent my woodstove and oil furnace on the same flue?

How do "air cooled" and "solid pack" chimney systems differ?

GAS HEATING STOVES & FIREPLACES

invisible

Do any gas stoves or gas fireplaces work without electrical power?

GETTING STARTED WITH WOOD BURNING

invisible

Why do I need to install a stainless steel liner for my wood stove or insert?

How do I start a good fire in my new wood stove?

Why does my chimney have poor draft?

Inside Chimney vs. Out Side Chimney. Does it matter?

What does house pressure have to do with my wood stove?

What makes good firewood?

GAS FIRED FIREPLACE INSERTS

invisible

How do fireplace gas log sets and gas fireplace inserts differ?

Have another question? We’d be glad to answer it for you.

Call (315) 589-4011 or e-mail us at customercare@williamsonace.com today!

Contact Us

4101 Main Street P.O. Box 163

Williamson, NY 14589

Phone: (315) 589-4011

Real People Answer Our Phones During Business Hours

Fax: (315) 589-2150 Email: customercare@williamsonace.com

Store Hours:

Monday – Friday: 8am to 6pm

Saturdays: 8am to 5pm

Sundays & Holidays: 9am to 3pm

Closed: Easter, Thanksgiving, Christmas & New Years

A fireplace is installed through an unused wall or corner of your home. If you are interested in adding a unit to an existing hearth opening see the insert or stove section of our site.

A fireplace is installed through an unused wall or corner of your home. If you are interested in adding a unit to an existing hearth opening see the insert or stove section of our site.

Fireplace inserts are used to convert an existing inefficient masonry wood burning fireplace or an old fireplace that is not operational to a highly efficient heat source for your home. Today, space heating has become very popular. That is heating only the space that you are using in your home and setting the thermostat back on the rest of the house to save money, yet keeping warm and cozy around your fireplace. Fire also provides the perfect atmosphere for social interaction, while watching the dancing flames, which awakens the senses of sight, sound and smell.

Fireplace inserts are used to convert an existing inefficient masonry wood burning fireplace or an old fireplace that is not operational to a highly efficient heat source for your home. Today, space heating has become very popular. That is heating only the space that you are using in your home and setting the thermostat back on the rest of the house to save money, yet keeping warm and cozy around your fireplace. Fire also provides the perfect atmosphere for social interaction, while watching the dancing flames, which awakens the senses of sight, sound and smell.

Electric Fireplace Inserts can be placed in an existing fireplace opening or inserted directly into a wall. These units provide the convenience of an electric fire with the ambiance of a gas or wood-burning unit.

Electric Fireplace Inserts can be placed in an existing fireplace opening or inserted directly into a wall. These units provide the convenience of an electric fire with the ambiance of a gas or wood-burning unit.

Coal stoves were once thought to be an “old fashioned” method of home heating. With the recent increased expense of gas, electricity and oil, people are again looking to coal-burning stoves and furnaces as a home heating option.

Coal stoves were once thought to be an “old fashioned” method of home heating. With the recent increased expense of gas, electricity and oil, people are again looking to coal-burning stoves and furnaces as a home heating option.